Our Warranty Policy is contained within our Ordering Terms, Policies, and Conditions page. We are committed to providing the best customer service and support possible.

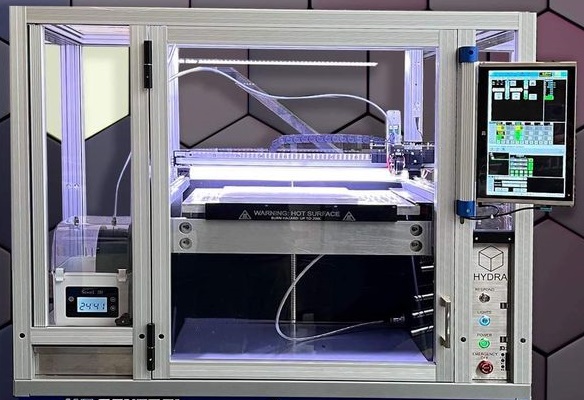

Hydra 21

THE HYDRA 21 – The Benchtop Workhorse

High Reliability - Low Maintenance - High Uptime - Heated Enclosure - Large Volume

- The Hydra 21 has a 300x400mm (optionally 400x500mm) bed, heated to 120C (optionally 200C).

- The enclosed build environment can be heated by the hotbed, and the filament storage protects your build and material from outside environmental changes

- The Hydra 21 printers work with all Hyrel print heads, allowing you to work with numerous materials, including store-bought or home-made filaments, clays, pastes, hydrogels, photo-initiators, and cementitious materials

- Designed with safety in mind

- Rugged, all-metal design

- Includes interchangeable mounting system

- Plug-and-play modular heads

- Ready for upgrade/expansion options

- Compatible with large volume extruders

- Optional 200C hotbed (larger than 300x400mm requires 208 or 220VAC)

- Optional 3-Phase Spindle Tool

- Optional Chilled and/or Vacuum Beds

- Hydra 21: 250mm Z, with the following bed options:

- Bed 43W is 400×300, 120°C

- Bed 43H is 400×300, 200°C

- Bed 54W is 600×400, 120°C

- Bed 54H is 600×400, 200°C

Note, Hydra 21 models all come with a 300x300mm magnetic plate and a 300x300mm PEI-powder-coated spring-steel build surface. Printing on the larger heated bed area will require you to remove the magnetic plate and add 12mm of glass or other build surface.

TECH SPECS

BUILD VOLUME

- X Axis 400 mm (opt. 500 mm)

- Y Axis 300 mm (opt. 400 mm)

- Z Axis 250 mm

POSITIONAL ACCURACY:

- X Axis+/- 60 microns

- Y Axis +/- 60 microns

- Z Axis +/- 10 microns

POSITIONAL RESOLUTION:

- X Axis 6 microns

- Y Axis 6 microns

- Z Axis 1 micron

CHASSIS & ENCLOSURE:

- Powder-coated Steel & Anodized Aluminum

- Plastic Windows

MOTION CONTROL:

- Three Precision Ball Screws in Z-axis

- Precision Linear Bearing System in X, Y, and Z Axes

ELECTRONICS:

- State-of-the-art 150+ MHz 32-bit ARM processor

- Modular, micro-stepping motor-drivers with closed-loop encoding

- Integrated, Dual CAN-bus architecture

- “Smooth Move” motion control technology firmware

TABLET PC:

- USB: Four USB 2.0 Ports (External)

- WLAN: WiFi Capable

PHYSICAL DIMENSIONS

OVERALL DETAILS:

- Weight: 300 lbs / 136 kgs

- Length: 42 in / 107 cm

- Width: 24 in / 61 cm

- Height: 33 in / 84 cm

ATX POWER SUPPLY SPECS:

- Power: 750 W

- Voltage: 115 / 230 V

- Current: 16 / 8 A

- Frequency: 60 / 50 Hz

- Physical On/Off Switch: Yes

- IEC-60320 C14 connector

- IEC-60320 C13-to-NEMA 15 Power Cable

- US Standard (International must supply own)

COMPATIBLE HEADS

HOT FLOW HEADS:

- MK1-250

- MK2-250

- HT1-250

- HT1-450

- HT3-250

- HT3-450

HEATED/CHILLED RESERVOIR HEADS:

- VOL-25

- KR2-15

- TAM-15

- HSD-30

- RSD-30

AMBIENT RESERVOIR HEADS:

- EMO-25, EMO-XT

- SDS-1, -5, -10, 30, 60

- SDS-30XT, 60XT, 150XT

OTHER HEADS:

- Spindle Tools

- Diode Lasers

- Extra Cooling Fan

- Microscope

- Extra Axes (4th, 4th/5th combo)

WHAT IS INCLUDED

- Enclosed HYREL 3D Printer with power cord

- USB ports for peripherals

- Five tool positions for print heads

- Tablet PC with Windows 10 and all software, firmware, and drivers installed and tested

- Large (see above) Heated Build Area

- Chamber Lighting

- Emergency Off (EMO) Button & Illuminated Control Panel